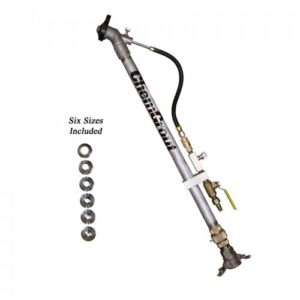

Applications

soil & rock, void filling, waterproofing, anchor, cable, rock bolts, encasements, marine/underwater, well casing, abondon shafts/holes, post tensioning, machine base, underlayments, undersealing, slab raising & bridge rehab.

Specifications

| Progressive Cavity Pump Model | Mixing Tank | Holding Hopper | Max. Output | ||

| CG550/2C4 CG550/3C4 |

2 Stage, Size 4, Open Throat 3 Stage, Size 4, Open Throat |

12 Gallon |

Requirements, Weights, and Dimensions

| CG550/2C4/A | Skid Mounted Air Powered Grout Plant Requires 150 CFM, 100 PSI |

700 lbs

|

|

| CG550/3C4/H | Skid Mounted Hydraulic Powered Grout Plant Requires 12 GPM, 1200 PSI |

600 lbs

|

|

| CG550/2C4/EHS | Skid Mounted Electric/Hydraulic Grout Plant Requires 230 V, 36 A, 1 Phase |

1000 lbs

|

|

| CG550/2C4/EHT | Skid Mounted Electric/Hydraulic Grout Plant Requires 230/460 V, 36/18 A, 3 Phase |

1000 lbs

|

|

| CG550/3C4/GHES | Skid Mounted Gas/Hydraulic Grout Plant Self-Contained 13 HP Honda Gas Engine |

1000 lbs

|

|

| CG550/2C4/DHES | Skid Mounted Diesel/Hydraulic Grout Plant Self-Contained 10 HP Diesel Engine |

1150 lbs

|

|

| CG555/2C4/GHES | Trailer Mounted Gas/Hydraulic Grout Plant Self-Contained 13 HP Honda Gas Engine |

1550 lbs

|

|

| CG555/2C4/DHES | Trailer Mounted Diesel/Hydraulic Grout Plant Self-Contained 13 HP Honda Diesel Engine |

1700 lbs

|